As9100 Certification Process

As9100 standards apply to aerospace quality management systems qms.

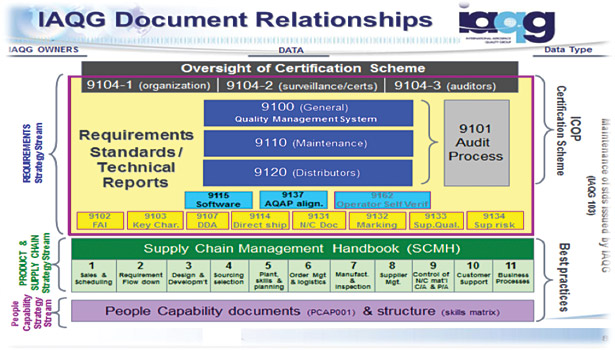

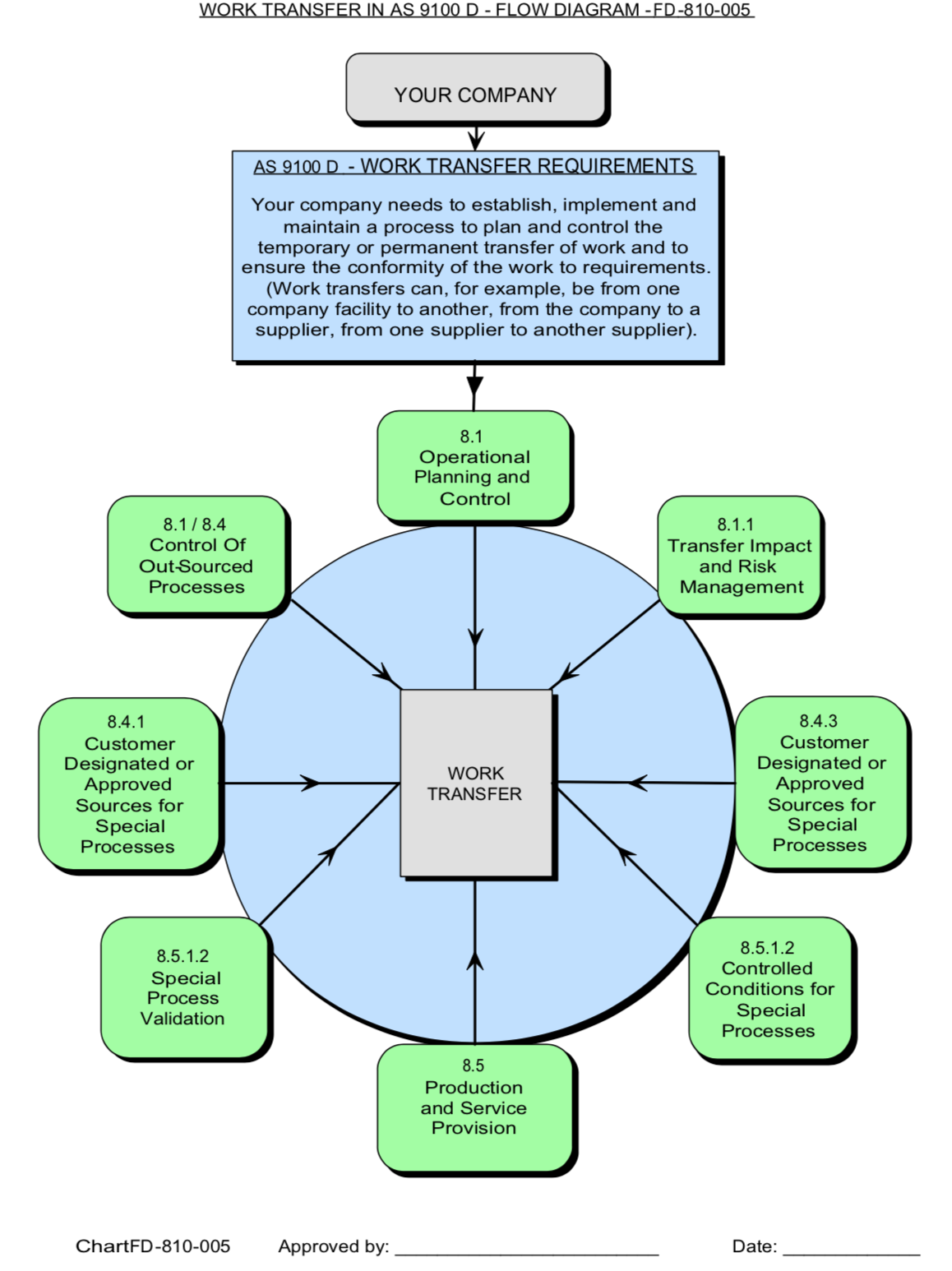

As9100 certification process. These processes are then audited for certification. When you get beyond standards certification in aerospace there is also on time delivery pressure. Learn about the standard. So where as9100 is an aerospace standard that gives requirements to implement and maintain a qms for the aerospace industry nadcap accreditations are used to ensure that a supplier meets all of the necessary criteria for a certain special process.

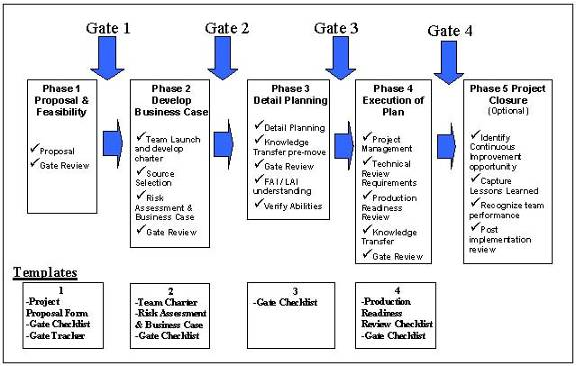

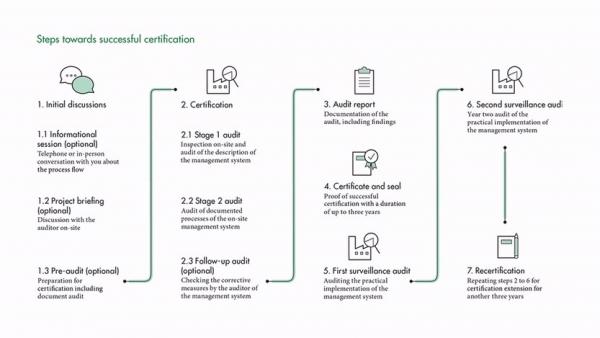

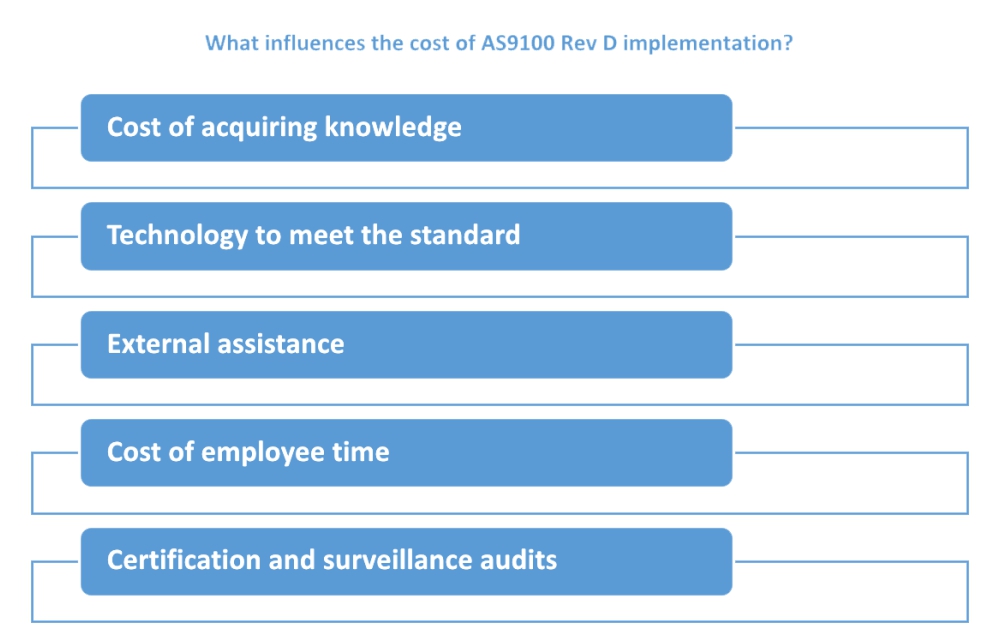

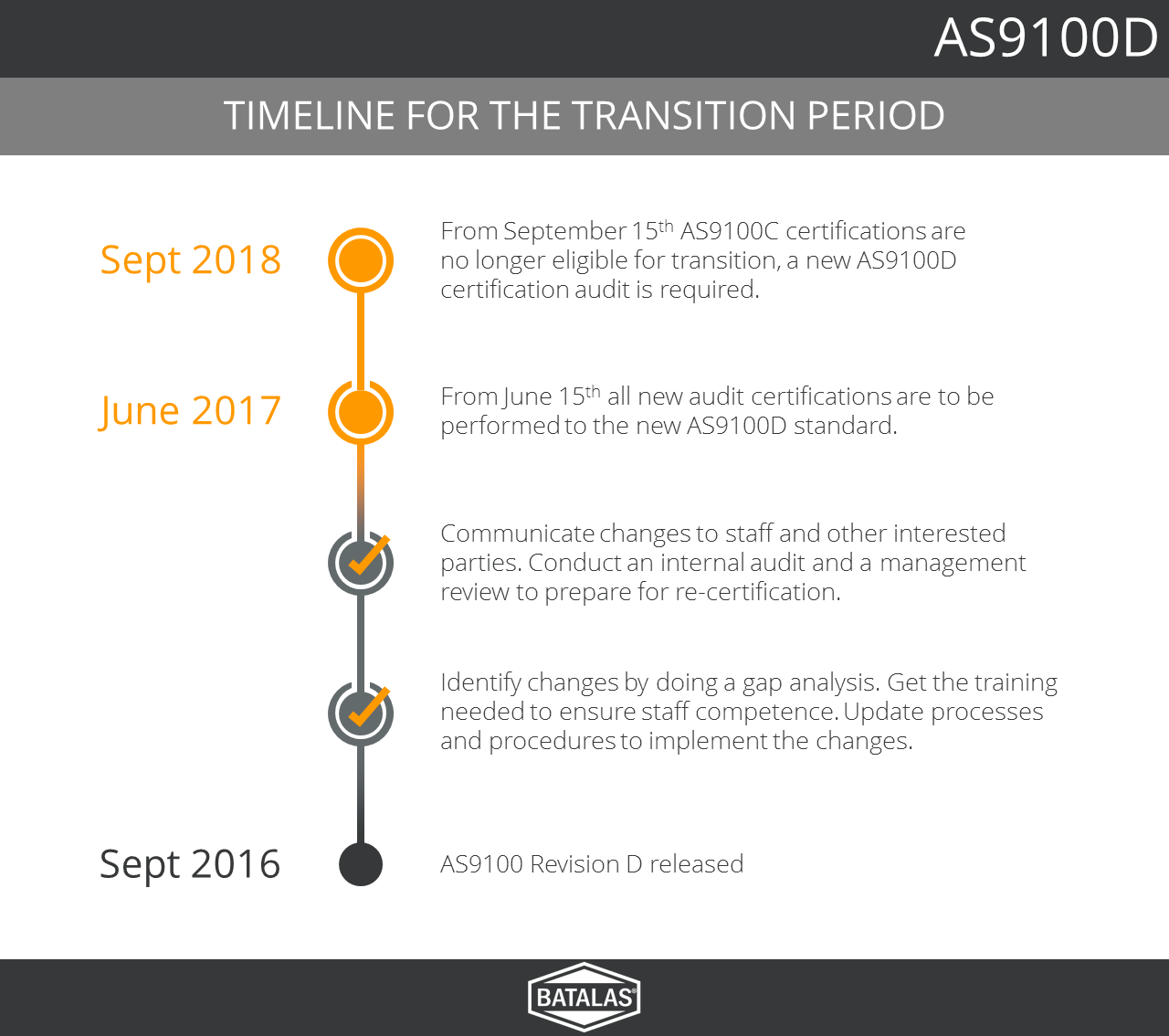

Steps to as9100 certification. In a previous article 13 implementation steps for as9100 rev d we discussed the entire implementation process and in this article we focus on the as9100 certification process and how this works. Implement your qms and conduct business. The elements of certification for your qms can have a critical impact on how useful your certification can be.

Under as9100 organizations must carefully watch these processes for improvement opportunities using methods like risk based thinking and the pdca cycle. With the tips provided above and your full commitment to the process you can ensure that your as9100 certification endeavors will go along as planned. The standards are international and were developed by the society of automotive engineers and the european association of aerospace industries. Perform a gap analysis.

This will determine if your companys qms standards have satisfied all as9100 requirements. Once a company completes the as9100 certification process with an accredited aerospace certification assessor it will receive a certificate that denotes as91002016 including iso 90012015 requirements troschinetz says. These progress focused process approaches in the as9100 help businesses improve accountability and process integrations on a continuous basis.